What is letterpress?

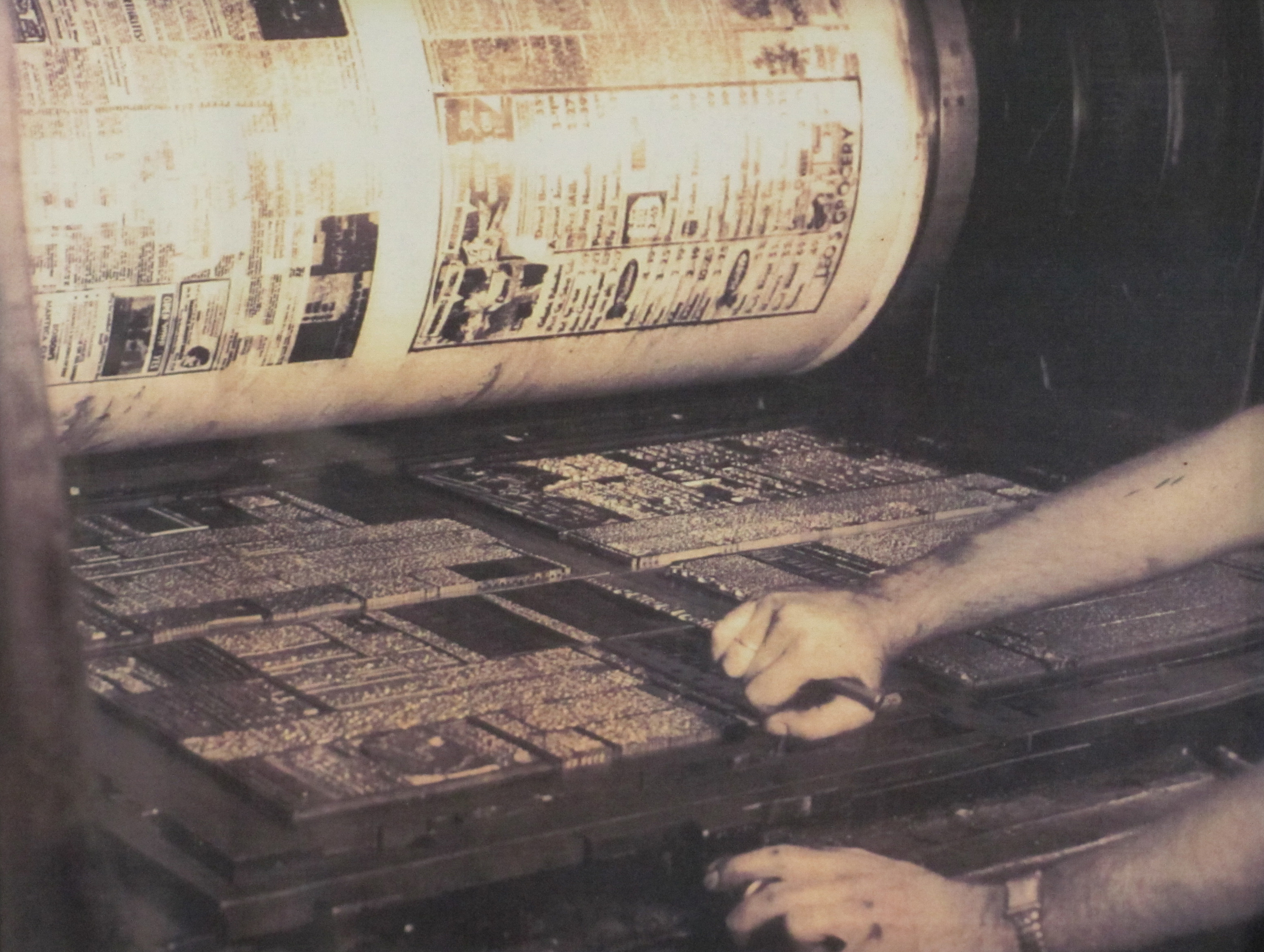

Technically known as Relief Printing, letterpress printing uses type or images that are inked by rollers and then “pressed” into the paper. The paper is fed into the press one sheet at a time – usually by hand – and each color or design change on a given print means each sheet is fed into the press again. The result is a tactile imprint that can be felt on the paper as well as seen.

Developed in Asia as early as 868 AD, this method of printmaking replaced the only existing method of producing texts, which was to handwrite the original and any copies of it. Early letterpress documents were made with wooden or metal blocks using wax, resin, or ashes from paper. After a few centuries, letterpress printing was widely used in Asia with printers improving and refining the process, most notably during the 11th century when moveable type was invented in China. The western world would not be introduced to letterpress printing until 1439 when Johannes Guttenberg began using the printing technique in Europe – some 600 years after being invented in Asia.

Letterpress printing was replaced by modern-day offset printing techniques, but in the last decade has once again become a popular form for printing special occasion paper items, business and personal stationery, wedding invitations, and greeting cards. There has not been a letterpress machine produced anywhere in the world since the late 1960s, and the majority of the machines operating today are over 100 years old. Most letterpress printers operate small print shops as hobbies or small businesses.

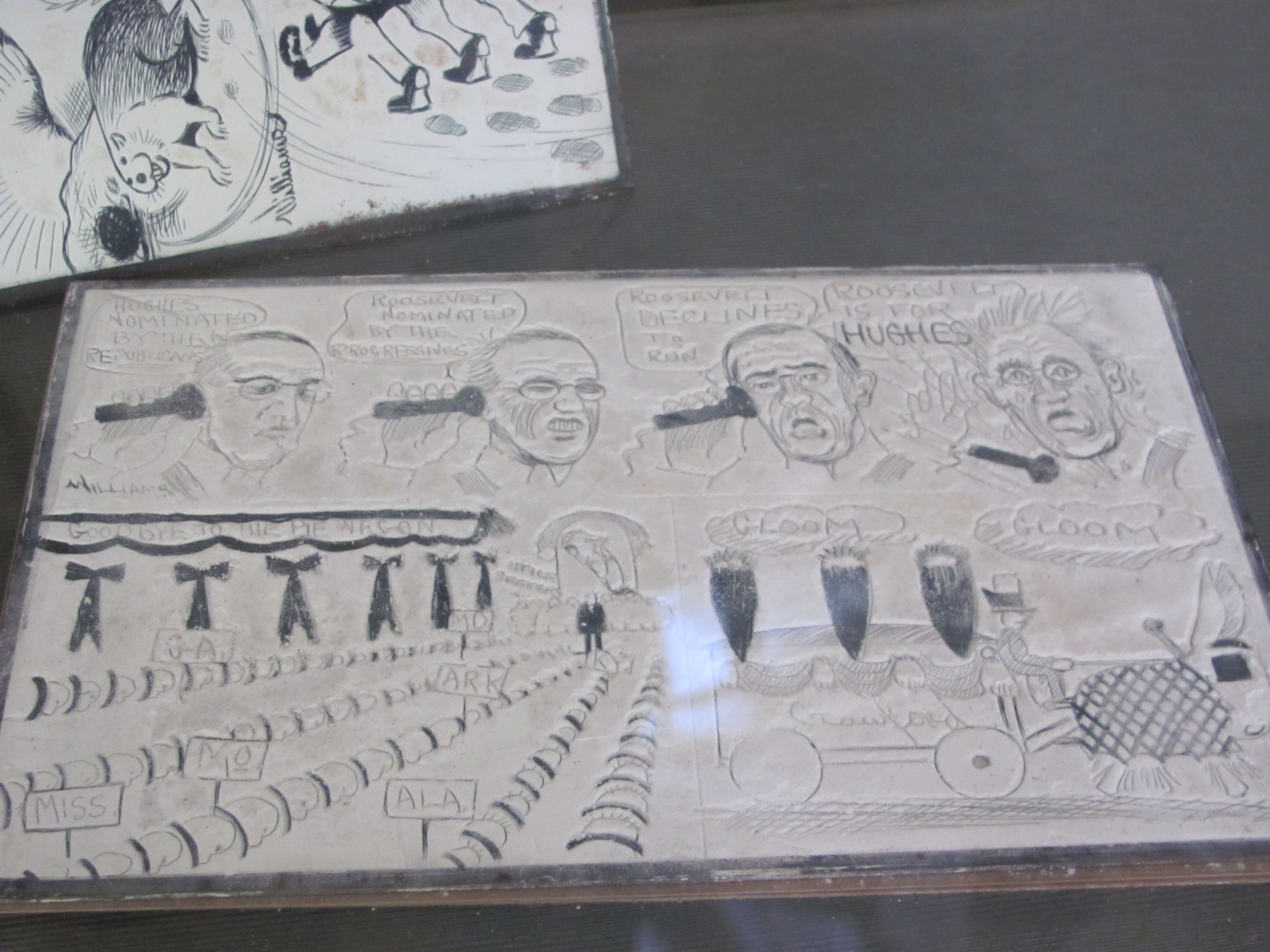

Methods of producing the type or images have been modernized. In the past, plates were often made from wood, metal, or other materials that could stand up to repeated pressure on the press. Artists and designers created artwork by hand and cast the engraving to create a plate (see the pic below of a chalk engraving used to create a plate in the 1930s).

Typesetting is becoming rare as on-demand letterpress printing is too expensive. Letterpress printers largely use polymer plates, instead of type that has to be set by hand, that are produced specifically for a given project. Each color in a design produces a separate plate. The plate (or plates for designs with two or more colors) are then attached one at a time to a printing base by an adhesive on the back of the plate and printed on the paper. For designs with more than one color, the press has to be cleaned, the next plate mounted, and then the sheets are fed again through the press one at a time, by hand.

It is good to note, traditional letterpress printing is prepped in a different manner. This is why we refer to Bloom Letterpress & Design as a ‘modern’ letterpress studio. Many letterpress printers still use traditional methods (metal type, registering design on tympan paper, etc.) and lots use both! Still, the process of letterpress printing is exactly the same as it was over 100 years ago, except in some cases, the only change is what is being inked (i.e., the plate as opposed to metal type). The press, however, has not been altered and operates exactly the same way it did over 100 years ago.